It’s been a month and a half since the last beta test has started so here's a quick catch up how things are going.

How is the test going?

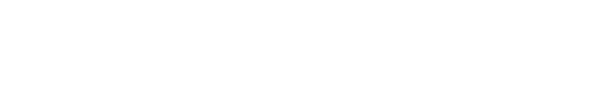

Épée test was going as planned and we will share the results in a follow-up post. Foil test was not so smooth and was delayed on a broad basis because of a hardware change. We have tested on those slightly modified devices in a local clubs and the results were similar to épée. So we decided that it is what will go into production. Few more non-critical tests remain to be done but production is finally in eyesight. So here's the latest production roadmap.

Production is set to start in less than 2 weeks and we will ship the preorders as soon as the first boxes got ready.

How did the system work so far?

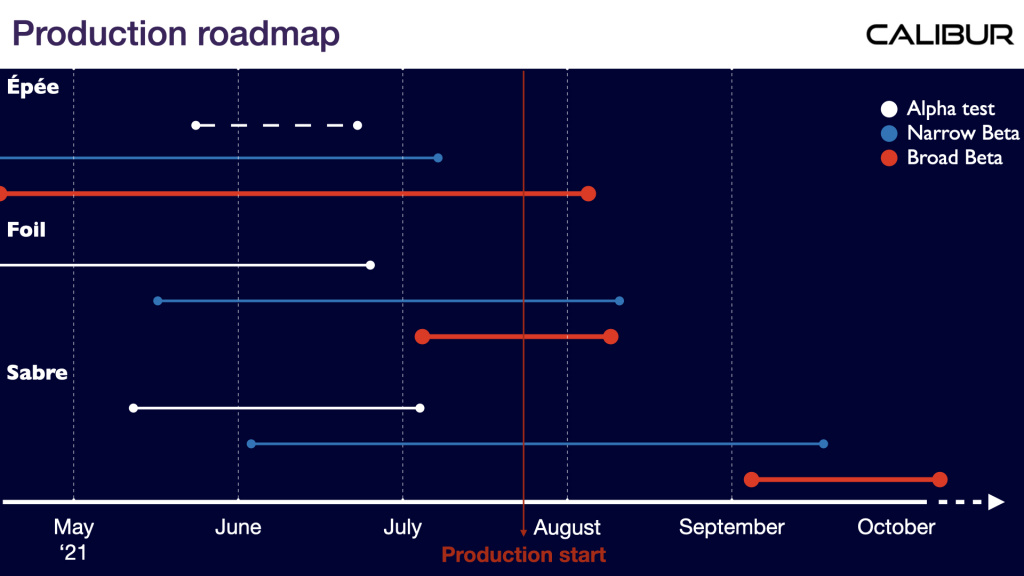

According to the feedback and the data the pocket boxes worked pretty much as expected. For all the things that can vary from one training venue to another it is hard to find a measurable pattern that's true in Florida and Sweden on new, state of the art blades and on rusty old ones. We still have a lot to polish on the software side but it's very clear now which direction to go. So there will be only minor changes to the underlying hardware, like:

Noise filtering

One thing that affected consistency is the level of wireless noise. In most training venues it’s not really a problem. However in busy places, where there are a lot of WiFi routers, antennas, the noise can create inconsistent results. Since we always fence in the office, we’d need to solve this issue at least for ourselves :).To be honest nothing beats a well designed hardware filter in that area. We have already built and tested it and it significantly improves performance in noisy areas.

Speed

It wasn't surprising that fencers would want fast feedback and we put a lot of emphasis on its development. That's why we have stripped down the test app to the bare minimum to make sure nothing affects latency. What was surprising where latency resides. There are 3 steps included: measuring on pocket box, wireless sending, processing on the phone. We have guessed that sending will be the bottleneck but as it turned out the processing is what takes the lion's share. We have developed during the past weeks a new method and it will be released to testers.

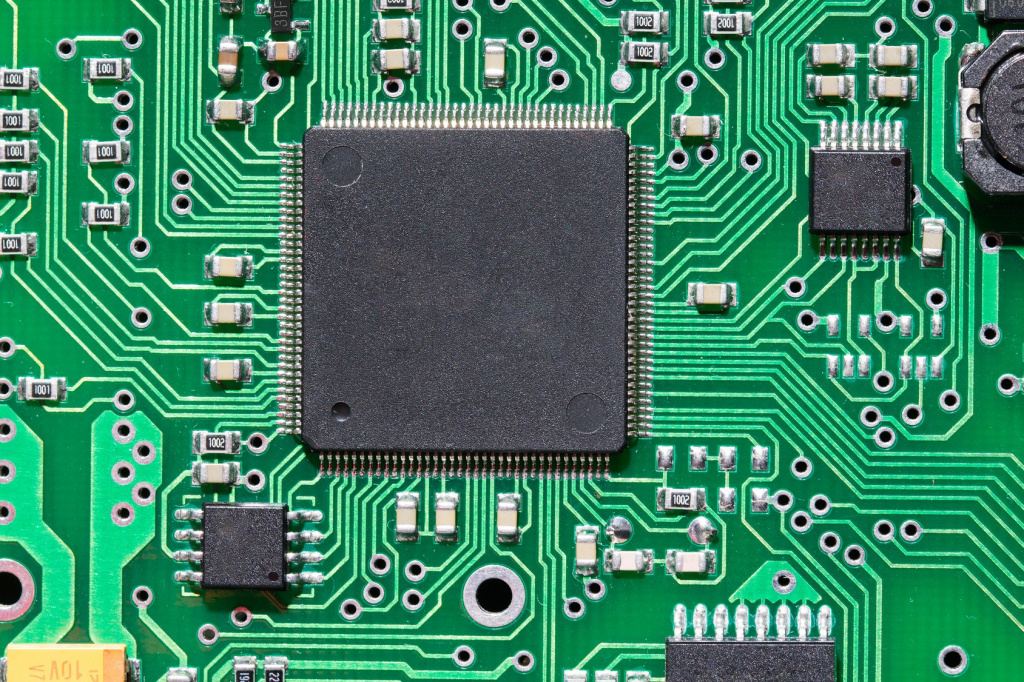

Enclosure

To make consistently good quality enclosures without tooling for mass production is a different kind of sorcery. To make a few hundred for testing was really a mess. We put in a lot of work to improve the process of making the boxes and their design was also slightly changed. Ultimately the solution will be to level up the manufacturing toolset to the next level. We can start production manually but eventually we would need to automate the process.

After a long and challenging development process it is good to see some light at the end of the tunnel. To be honest it's both exciting and a bit frightening. Stay tuned, as we are preparing an announcement for the occasion.